Food processing is one of the fastest-growing industries across the globe. The contribution of the food industry to the Gross Value Added, employment, and investments has a significant share across the globe. The growth of this industry is solely based on the availability of raw materials. Whereas, concerning instruments and equipment, a wide chunk of such equipment is used in the food industry.

Moreover, the things and scenarios that contribute to the increasing trend of international food processing technology, are rising demands of the quality food products, and the ever-increasing need of customers to fulfill their expectations requires more advanced and denser technology variants.

The food processing equipment varies concerning the production cycle of that respective industry, their specific operative functions, and performing of individual unit operations. The processing starts with the primary function that involves preparing the food material for further processing as well as washing or separating. Then there comes the material handling and system control operations which convey food materials between process stations or maintain the required processing conditions and standards.

Processing

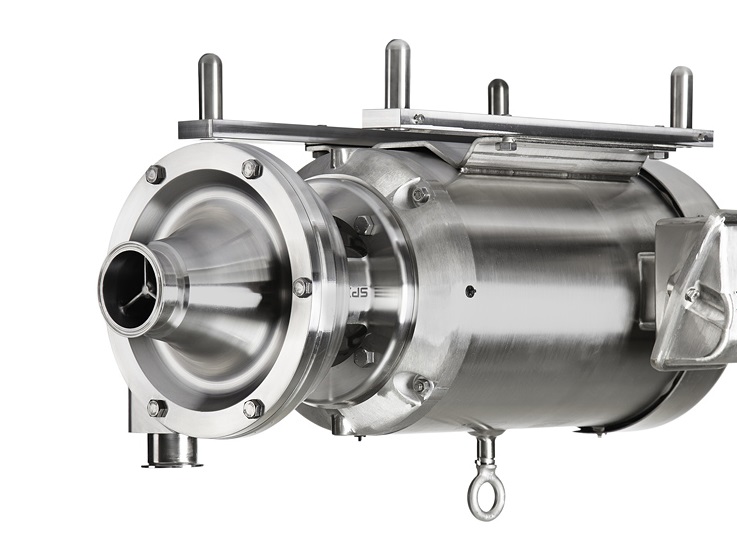

Food industry equipment at first involves processing equipment which involves mechanical and chemical processing—separating concerning the material from undesirable material. With this approach, manufacturers could ensure the production of a uniform and high-quality food products with no traces of foreign contaminants that may degrade or damage the food material.

The next step involves Heat processing equipment that might be used to tackle the heating or cooling of the food material. These heat transfer equipment are used to direct heat towards or away from the material for rapid cooling or heating of the food material.

The best amongst all heating and processing equipment are the ones that soothe every process during the processing phase and sustain the quality of the food material to make it even better for consumer use. Heating equipment should provide the exact heat needed to heat the materials and avoid the transfer of excessive heat that might damage the final product.

The heat processing and cooling phase involve blanching, baking, dehydration, frying, evaporation, pasteurization, roasting, and sterilization. These processes should be carried out with quality equipment that is best via deliverance and sustainability. A proper brand name with a reliable equipment network or inventory could be the better solution for these equipment needs. SO don’t get fooled from a local manufacturer or irrefutable manufacturer.

Always buy from a reliable manufacturer or providers like Industrial Freezing which offers a long range of processing and heating equipment as well as the freezing solution for all your processing, heating, and freezing needs. Just reach out to us and we will be there with immediate and best possible solutions for all your needs.