Garages are generally associated with two things – junks and tools. But in all these worthless and forgotten junks, you can always find something useful. Like earlier said, the garage is known for its wastes and tools, and these tools come quite handy many times around the house. Tools range from a cordless saw to a hedge trimmer, which always ends up being useful in the long run. One such helpful tool is a circular saw, which is used for many things, ranging from major construction to simple tasks around the house. It is a powerful tool with a round blade for making a clean cut on wood, plastic, paneling, and concrete board. Some come with specialized blades designed to cut through metal sheets. A circular saw can be used to make a series of cuts such as the rip cut, crosscut, and plunge cuts. Circular saw may be handheld or mounted to get better stability.

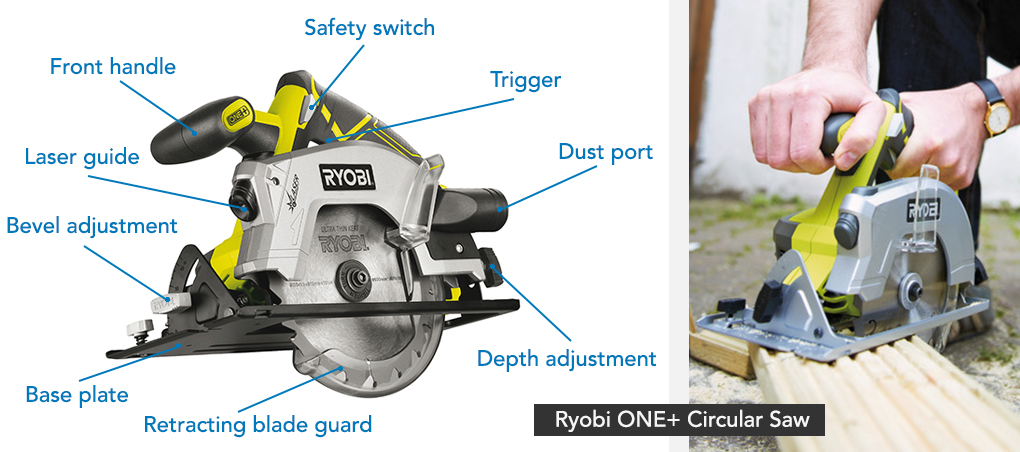

Parts of a Circular Saw

Before you can conveniently use a circular saw, it is crucial to be familiar with what makes up the saw and their functions.

Blade Cover:

This covers the blade’s top and bottom, leaving an opening in front of the blade where it does all the cutting. The primary function is to protect the handler from injuries or damages an object may incur from accidentally coming in contact with the blade. Aside from this, it prevents debris from flying about when you are working.

Bevel Adjustment:

Bevel adjustment is located in the front of the saw, a little off to the side. It is used to adjust the bevel angle during cutting. Bevel adjustment enables you to make different angles on the object you are cutting quickly, and once the change is made, it is secured with the knob attached to the plate.

Blade:

The blade is one of the main functional parts of the circular saw and is responsible for all the cutting. It comes in different variations, but there are four essential parts of the blade: tooth configuration, a number of teeth, hook angle, and gullet size. Saw blade with a high number of teeth gives a finish cut that looks polished and smooth, although it is a bit difficult to get through a piece of wood. At the same time, a saw blade with fewer teeth works through a piece of timber faster. The finished cut is a bit rough—also, the more infrequent the gullet teeth, the faster the feed rate and vice versa.

Bot Clamp:

The bot clamp only function is to secure the blade to the circular saw.

Plate:

The plate is located in the middle of the saw (lengthwise) and also surrounds it. It allows the saw to sit down on objects while sawing, keeping it steady and stable. It can also function as a guide when moving the saw along with the purpose.

Handle:

This is used for holding and maneuvering the saw when in use. It makes it stable too. For most circular saw, the handle is comfortable 5o use.

Power Switch:

This is used to turn the saw on/off once powered and is located beneath the handle.

The circular saw is an item every dad should have in the garage, check out this article from Safetyhub to learn more.

How to Operate a Circular Saw

There are steps to take when using a circular saw and they are outlined below, this will help you familiarise with the saw and aid the smooth operation of the saw

- Please familiarise yourself with the circular saw: it is essential to know the brand of circular saw you are using although we have a variety of saw, they have the same basic design. You hold the saw by the handle and use the trigger to control the movement.

- Safety precautions: it is crucial to put some precautions in place before using the circular saw. It is good to equip yourself with gloves and safety goggles, and if you are going to be using the saw for a long time, then an earmuff is recommended.

- Measure and mark the materials: this can be done with a ruler, carpenter pencil, or pen to make precise measurements of where you will be cutting. Once the size is created, using the circular saw to cut is more comfortable.

- Balance your material on a saw table or sawhorses: this is done to aid smooth movement if the saw with no obstruction underneath. Placing your content on an ordinary table or floor can damage both the saw and the surface.

- Set the central lever: after you have balanced your material on the saw table, place the saw on the content and use the lever to set the blade to your desired cutting depth. After that, you adjust the pivoting scale to angle the blade for cutting.

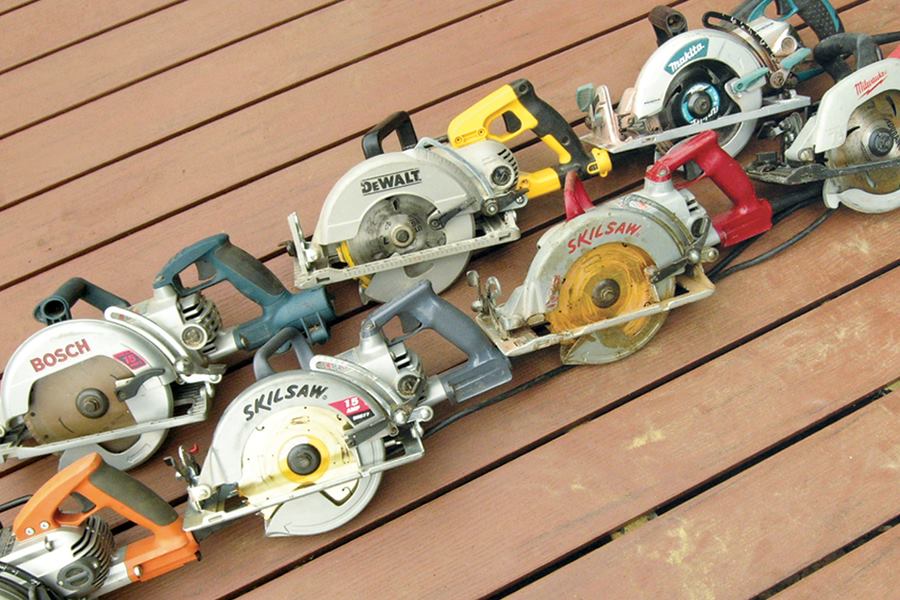

Types of Circular Saw

Circular saw comes in different types and sizes, here are some of the popular ones:

Worm Drive

The motor of a worm drive is located towards the back of the saw resulting in a narrow shape. This makes it easier to carry out plunge cuts and also to cut more full boards. A worm drive is without its vice, as it is challenging to maintain. It involves adding oil now and then to keep it in good shape.

Sidewinder

This is one of the most popular circulars saw, with its lightweight and compact body. The motor is located towards the side, which contributes to its portability. It weighs less than other circular saw and is most suitable for overhead cuttings since the engine is situated beside the blade, it spins faster than most circular saws. Generally, it is the ideal saw in terms of speed, convenience, maintenance, and weight. However, one downside to it is that it lacks the power to make deeper cuts.

Hypoid

They are similar to worm drive in terms of look and are often mistaken for it. The saw coined its name from the hypoid gear it uses. The hybrid design helps increase efficiency and blade contact. The size is smaller due to the hybrid design, and the noise reduced, plus it requires little maintenance as it possesses a sealed motor system. Although hypoid saw is compact and efficient, it is massive and costly.